In the ever-evolving landscape of manufacturing, efficiency is paramount. Companies are constantly seeking innovative ways to streamline their production processes, reduce costs, and improve product quality. One such revolutionary method that has transformed manufacturing is die casting. This article delves into the intricacies of die casting services and how they have revolutionized the manufacturing industry.

What is Die Casting?

Die casting is a manufacturing process that involves injecting molten metal into a steel mold, known as a die, under high pressure. Once the metal solidifies, the die is opened, and the casting is ejected. This process allows for the production of complex shapes with high precision and repeatability.

The Advantages of Die Casting

Die casting offers numerous advantages over other manufacturing processes, making it a preferred choice for many industries. One of the primary benefits is the ability to produce parts with tight tolerances and excellent surface finishes. This is crucial for industries such as automotive and aerospace, where precision is paramount.

Additionally, die casting is highly efficient, with short cycle times that enable high-volume production. This efficiency translates to die casting production costs per part, making die casting a cost-effective solution for mass production.

Furthermore, die casting allows for the use of a wide range of metals, including aluminum, zinc, and magnesium. Each of these metals offers unique properties, allowing manufacturers to choose the most suitable material for their specific application.

The Role of Die Casting Services

Die casting services play a crucial role in the manufacturing ecosystem by providing expertise and resources for companies looking to leverage the benefits of die casting. These service providers typically offer a comprehensive range of services, including mold design and fabrication, material selection, and production optimization.

By partnering with die casting services, companies can benefit from the extensive experience and specialized knowledge of die casting professionals. This collaboration enables manufacturers to optimize their designs for the die casting process, ensuring maximum efficiency and quality.

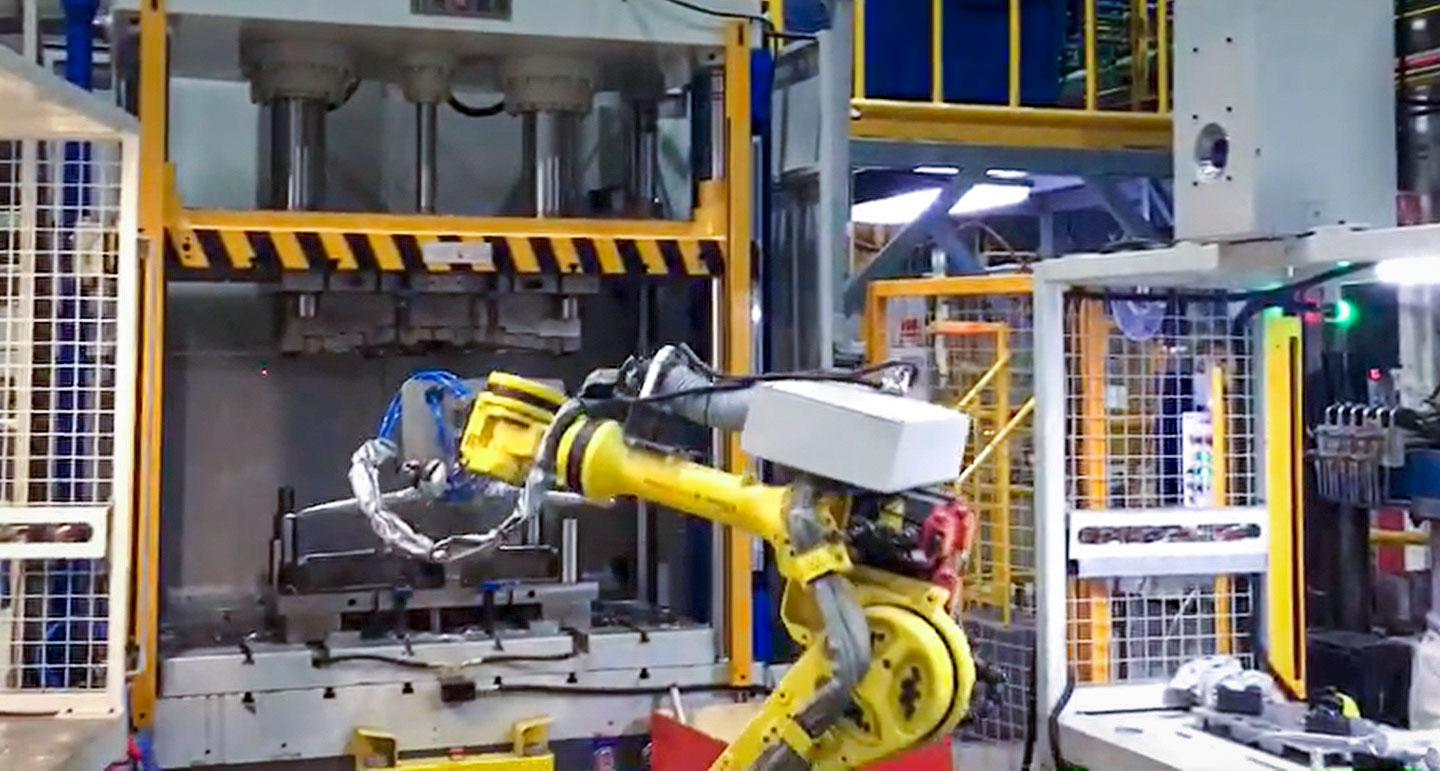

Moreover, die casting services often invest in state-of-the-art equipment and technology to enhance productivity and quality control. This includes advanced die casting machines, robotic automation, and sophisticated inspection systems. By leveraging these resources, die casting services can deliver high-quality parts with minimal defects.

Applications of Die Casting

The versatility of die casting makes it suitable for a wide range of applications across various industries. In the automotive sector, die casting is commonly used to produce engine components, transmission parts, and chassis components. The lightweight yet durable nature of die-cast parts makes them ideal for improving fuel efficiency and performance.

In the electronics industry, die casting is utilized to manufacture enclosures, heat sinks, and connectors. The ability to produce intricate shapes with tight tolerances is particularly beneficial for electronic devices where space is limited.

Furthermore, die casting is extensively employed in the aerospace and defense sectors for producing components such as aircraft engine parts, structural components, and missile casings. The high strength-to-weight ratio of die-cast parts makes them well-suited for aerospace applications where weight reduction is critical.

Environmental Considerations

In addition to its numerous technical advantages, die casting also offers environmental benefits. The process generates minimal waste, as scrap metal can be recycled and reused in subsequent production runs. Furthermore, die casting typically requires less machining compared to other manufacturing processes, reducing energy consumption and material waste.

Moreover, advancements in die casting technology have led to the development of eco-friendly processes, such as the use of recycled materials and energy-efficient equipment. By adopting these sustainable practices, die casting services can minimize their environmental footprint while delivering high-quality products to their customers.

Conclusion

Die casting services have revolutionized the manufacturing industry by offering a fast, efficient, and cost-effective solution for producing high-quality metal parts. Through advanced technology, expertise, and a commitment to sustainability, die casting services continue to drive innovation and shape the future of manufacturing. As industries continue to evolve, die casting will remain a cornerstone of modern manufacturing, enabling companies to stay competitive in today’s dynamic market landscape.

Top of Form