Beyond Basics: Advanced Techniques for Rotary Vibrating Screen Applications

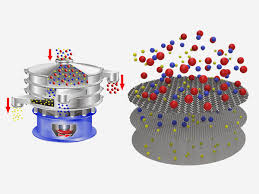

Rotary vibrating screens have become indispensable tools across various industries, facilitating efficient particle separation and sizing. While the basics of rotary vibrating screens are well understood, there exist advanced techniques that can elevate their performance to new heights. In this article, we delve into these advanced techniques, exploring how they can optimize rotary vibrating screen applications.

- High-Frequency Vibration

One of the key advancements in rotary vibrating screen technology is the utilization of high-frequency vibration. By increasing the frequency of vibration, finer particles can be effectively separated, enhancing the screen’s efficiency and throughput. High-frequency vibration also helps to reduce blinding and clogging of the screen mesh, ensuring continuous operation even with challenging materials.

- Variable Amplitude Adjustment

Modern rotary vibrating screens feature variable amplitude adjustment capabilities, allowing operators to fine-tune the amplitude according to specific application requirements. This flexibility enables precise control over rotary vibrating sieve screening process, optimizing performance for different particle sizes and materials. Variable amplitude adjustment enhances the versatility of rotary vibrating screens, making them suitable for a wide range of applications.

- Multi-Deck Configurations

Another advanced technique for rotary vibrating screen applications is the incorporation of multi-deck configurations. Multi-deck screens consist of multiple layers of screening surfaces stacked on top of each other, increasing the screening capacity and efficiency. By utilizing multi-deck configurations, operators can achieve precise particle separation across different size fractions, maximizing product quality and yield.

- Ultrasonic Deblinding System

To tackle the challenge of screen blinding and clogging, advanced rotary vibrating screens employ ultrasonic deblinding systems. These systems utilize high-frequency ultrasonic vibrations to prevent particles from adhering to the screen mesh, ensuring uninterrupted operation and consistent performance. Ultrasonic deblinding systems are particularly effective for screening fine and sticky materials, enhancing overall efficiency and reliability.

- Air Knife System

In addition to ultrasonic deblinding systems, some rotary vibrating screens feature air knife systems to combat screen blinding and improve throughput. Air knife systems use compressed air to dislodge particles trapped in the screen mesh, preventing buildup and maintaining optimal screening conditions. By combining air knife systems with other advanced techniques, operators can achieve superior screening performance across various applications.

- Advanced Motion Control

Advanced motion control technologies play a crucial role in optimizing rotary vibrating screen applications. By implementing precise motion control algorithms, operators can adjust the speed, acceleration, and trajectory of the vibrating screen, ensuring optimal particle movement and separation. Advanced motion control enables finer particle sizing, improved accuracy, and enhanced overall efficiency.

- Intelligent Automation

The integration of intelligent automation features further enhances the capabilities of rotary vibrating screens. Intelligent automation systems utilize sensors, actuators, and algorithms to monitor and adjust various parameters in real-time, optimizing performance and minimizing downtime. By leveraging intelligent automation, operators can achieve seamless operation, predictive maintenance, and continuous improvement in rotary vibrating screen applications.

Conclusion

Advanced techniques have revolutionized the capabilities of rotary vibrating screens, enabling precise particle separation, improved efficiency, and enhanced reliability across various industries. From high-frequency vibration to intelligent automation, these advancements empower operators to tackle the most demanding screening challenges with confidence. By embracing these advanced techniques, businesses can unlock new possibilities and elevate their rotary vibrating screen applications to unprecedented levels of performance and productivity.

Top of Form